Listen to me. This is not a post about tools. This is not a post about woodworking. This is a post about life. I’m not writing between the lines and I’m not allegorizing. I am trying to write as clearly as possible. I want you to understand.

Hand tool woodworking demands the use of the right tool for the job. I don’t mean this in any kind of puritanical or dogmatic sense. It’s mere practicality.

Depending on your goals, power tools and hand tools are both options for many tasks. The tools demand distinct approaches. If you were to use a hand saw for the same variety of tasks you use a table saw for, your work would suffer, your arm would suffer, and you’d give up.

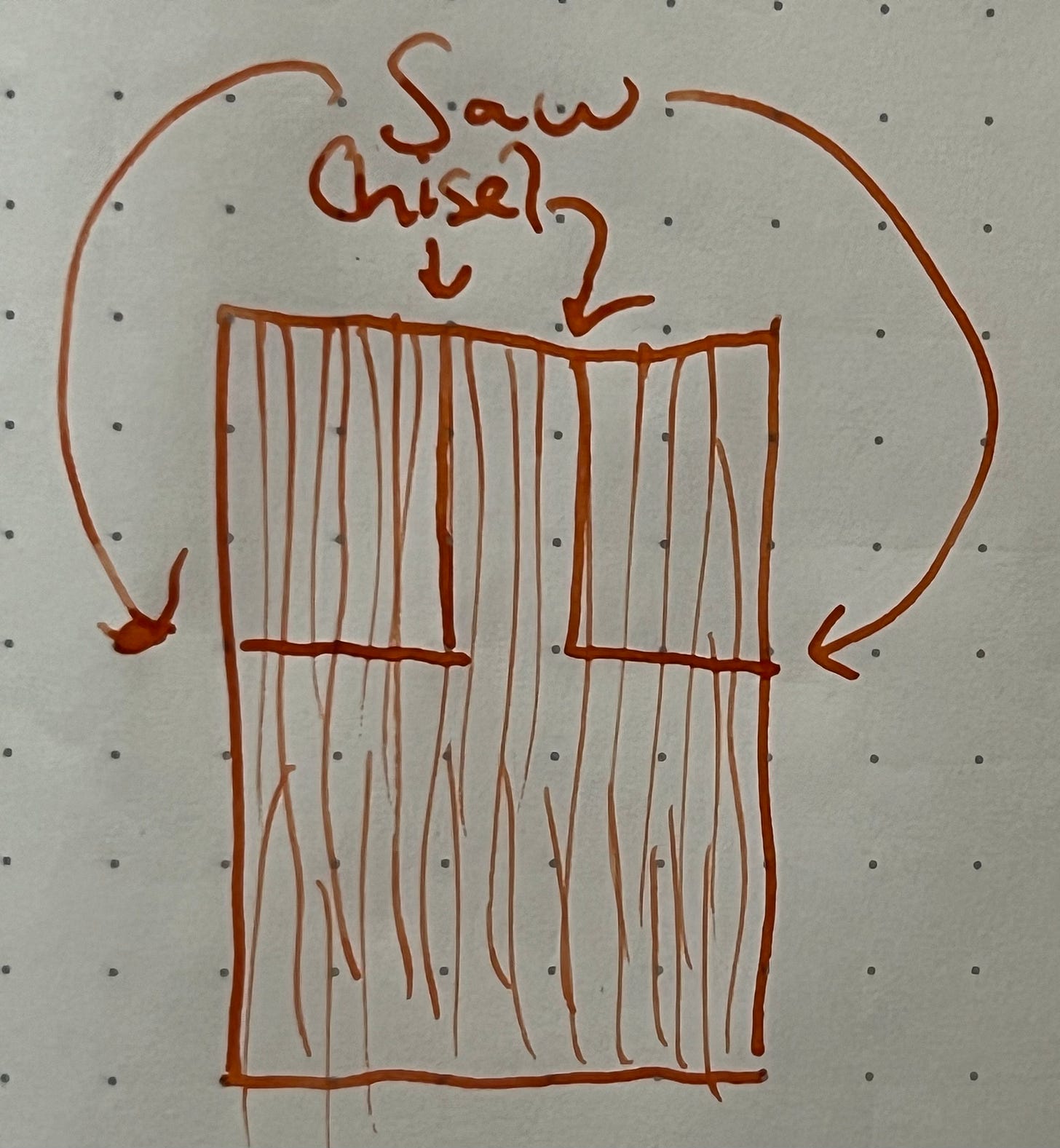

It is worth giving a little extra thought about what you are doing. Consider if there are better options. When you create a tenon, the most obvious way is to use a handsaw in both directions.

Using a handsaw to cut end grain is difficult and annoying1. A hugely easier option, if your wood cooperates, is to crosscut the shoulders and then use a chisel and a mallet to split off the rest.

The second option takes tens of seconds rather than minutes.

I am frustrated— even crestfallen— that no amount of explaining will give you the visceral understanding I’m trying to share here. That’s sad to me. This is a lesson that has impacted the way I think about everything I do.

My favorite tools are the tools I make myself. This is a theme I keep coming back to over and over.

On the second day of bench glue up I came to my senses and decided that cleaning up a rough benchtop with a smoothing plane (or even a jack plane) was absurd and that I needed a scrub plane. A scrub plane has a dramatically curved blade and takes out significant amounts of wood. When you use a scrub plane you can end up with a flat surface that’s not rough, but it doesn’t feel like glass, because you end up getting wavy undulations due to the camber of the iron.

On November 19, 2022, I used my hand crank grinder to introduce a curve into the blade of a Stanley 78.

I ended up needing to take a few attempts, but it doesn’t really need to be perfect. If you do a good job making your camber nice and symmetrical you’ll be able to have it protrude very slightly to take small shavings and gently advance it to make larger and larger shavings. If the camber is asymmetrical you’ll end up with less predictable adjustments. This is worse, but it’s also fine.

I got this idea from Paul Sellers. I honestly couldn’t say why a 78 is a good option for a scrub plane but at this point it’s my favorite plane. I can very quickly clean up some rough stuff and end up with an attractive and flat surface.

Prose cuts like an axe

Often I don’t even follow up with a smoothing plane afterwards. For my benchtop I didn’t. If a project involves planing, there’s a good chance I start with the scrub.

I could never enumerate a list or a set of instructions for “the right tool for the job.” I do have a rule of thumb that if I am doing the same task for more than one session of woodworking, I must be doing something wrong. It might be bad technique, it might be the wrong tool, or maybe some other problem (like needing to sharpen a saw.) This is my personal rule, and it should be adjusted to taste, but hopefully you see the glimmer of truth in it.

These instincts apply in any situation.

Professionally I’m a software engineer. A true but facile comparison here would be to compare different tools the way I might compare a document store and a relational database. A better comparison is the design work that I do before any code gets written. Writing code is like using a smoothing plane. It’ll work, but it’s an extremely subtle instrument. Prose cuts like an axe, letting you quickly sketch out what to do. Even better than a design is a frank conversation discussing whether or not to do anything at all. Many engineers fall into the trap of coding for it’s own sake. Avoid using a hand plane for the experience of it.

There’s an irony that I learned this doing the slow labor of hand tool woodworking.

A prior revision of this article used profanity to describe sawing end grain. I’ll show you the original if you ask nicely.

This is what good writing is about. Well written. To the point. Some useful learning points. Now I'm off to watch that Paul Sellers video again and make myself a scrub plan. Thanks Frew.