Router Plane

A Post about Wood with Holes

When I was little my dad had three boats: a sailboat, a motorboat, and a houseboat. Some of my earliest memories are on these boats. The first (only?) time I got seasick was on the sailboat. I got scared when a snake was swimming on top of the water toward me next to the houseboat. We watched fireworks from the sailboat on the 4th of July.

Some time between 1990 and 1993 dad, Walt, and I went to the sailboat to spend the night. My recollection is that the boat was anchored somewhere between the gulf coast and the barrier islands, but who really knows. You’re supposed to keep your boat outfitted with flares, glow sticks, and other emergency gear. These things expire and my dad was uncharacteristically conscientious about having this stuff ship shape. That night the three of us used up all of our glow sticks and flares just for fun. It was awesome.

When we finally settled down to go to sleep Dad was showing us shadow puppets with a flashlight. Eventually we all got punchy and I think either Walt or I covered the flashlight and made some kind of monster noise and we all had belly laughs. It was a good time…

A few months after I started this hobby Paul Sellers published a video about how to make your own router plane. I was completely transfixed, but almost everything he did in the video was new to me. I didn’t know how to plane, saw to a line, or even use a square. I added the project to my list but didn’t do anything immediately.

About a month later, Paul started selling a kit with the hardware you need to make this router plane. I purchased my kit and got the wood a few months later (27Jan2023.) I think I cut the stock to size the same day (and noticed that my rip saw was comically dull.)

The project lay fallow for over six months. It was waiting for me to develop the skills I would need to reliably build the plane. Two years after I first saw the video it was time to get going.

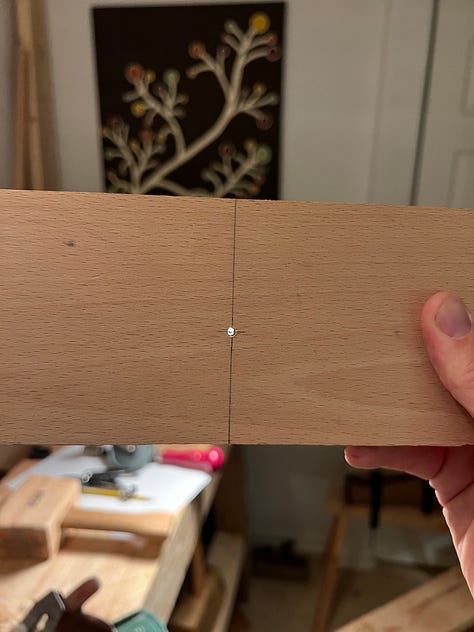

The first task is to create a tool that assists you in boring perfectly square holes. The most obvious way to do this task is with a drill press, but I was enchanted with this roundabout way to achieve the same task. The gist is that you use a saw and a small chisel to create a small channel that a 1/8” drill bit can go through. You create the channel 90 degrees to the face, which is a pretty common day-to-day task when woodworking. Next you glue another piece of wood so that the channel is no longer open. The face side of the tool sits flat on what you are boring a hole into, and the channel is perfectly square.

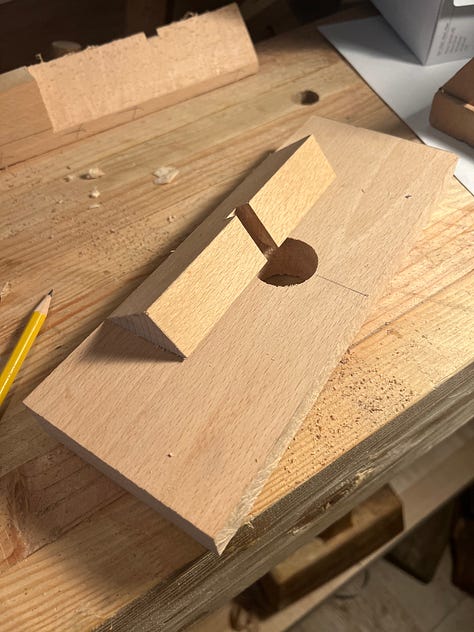

Initially the project was surprisingly easy, all smooth sailing. I made the throat, where the blade will live and do it’s cutting:

Next I made the “uplift” (I think this is what Sellers called it) which the blade mates with. A lot of other hardware gets mounted on this. The angles are important to get right.

Next I did some shaping of the body before gluing on the uplift. Gluing on the uplift would make holding the body in the vise much harder.

After shaping the body I shaped the uplift. All rasp and file work. I am still surprised at how well this turned out.

The calmest and easiest glue up ever:

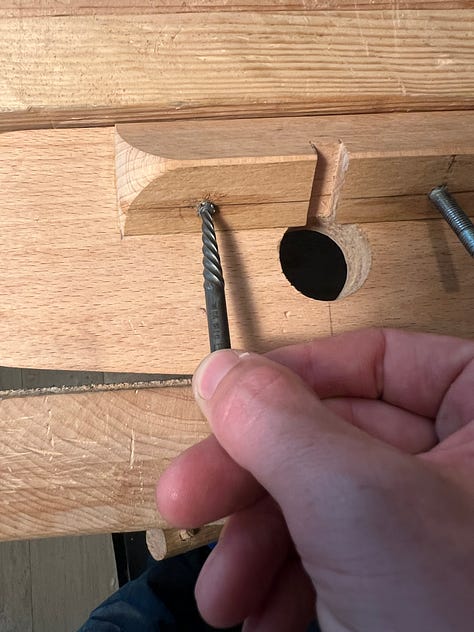

The first problem I ran into was screwing in the first hanger bolt. I wasn’t able to grip the machine side of the hanger bolt without damaging the machine side, so for the second one I decided to go get a pair of nuts to properly drive in the screw. Of course, the kit is all metric (Paul Sellers is from the UK) so I couldn’t go to my preferred hardware store due. They only have Freedom Units. I was screwing in the second hanger bolt and suddenly the screw started to go in too easily. I had sheared the stainless steel bolt in half.

I assumed I needed to just start over, but there was no rush. I would need more wood if I started over anyway, so I considered alternatives. My brother, well versed in metalworking, suggested using an “easy out.”

I considered what else could have caused this, with some feedback from my wood pals. I used 3/16” where Paul used a 5mm bit. The half millimeter reduction may have been too much! I don’t have metric tools, so I was using a wrench and an adjustable crescent wrench to screw it in; the wobbling could have stressed the bolt. I used a drop of oil on the hanger bolt, Paul used “furniture wax” which may have worked better for the entirety of the bolt.

I ordered an easy out set, a 5mm drill bit, borrowed some metric tools from a neighbor, and used paste wax instead of just oil on the next hanger bolt. I successfully extracted the sheared hanger bolt and then used the two nut trick to screw in a fresh one.

I was cooking with gas. I was able to reliably screw in the rest of the hanger bolts. I got the plane to a functioning state and was sure I was done. Unfortunately I had another curveball coming my way.

The plans call for a cabinet knob that’s about 1-5/8” projection by 1-3/4” diameter. Despite lots of attempts I couldn’t seem to find a knob like this at my preferred hardware store, Home Depot, Etsy, or Ebay.

Good thing I know how to make things out of wood.

I spent a few days making a pair of knobs out of some cherry. I think making the knobs took about the same amount of time as the rest of the plane put together. The overall sidequest was:

plane the blanks round

Rasp, fine rasp, file the top corner to a nice curve

Saw a relief cut between the top and the stem

Use a chisel to chop out the waste around the stem (my favorite part by far)

Rasp, fine rasp, file the bottom corner to a nice curve

Use the 1/8” pre-boring jig that the whole project leans on for accuracy.

This worked fine aside from the 5/8” countersink, which was not quite enough and I needed to chisel out some extra

After wrapping up the knobs, I assembled the rest of the router plane. It went pretty reliably.

Finally I finished the piece with boiled linseed oil and paste wax.

Another time Walt, Dad, and I were going out to the houseboat to spend the night. I think my mom was either pregnant with or maybe had just had the twins. I remember that my uncle Anthony and his wife Ruthanne were at home and my guess is that my dad wanted a change of scenery.

When we finally were on the motorboat to get to the houseboat it was twilight. Visibility was poor and the tides were low. On the way to the houseboat we hit a stump or a log. Walt’s face hit the front of the boat and we were taking on water. We pulled into some random private slip on the river and dad did what he could do (I think jammed a piece of wood into the hole.) Dad moved all the stuff in the boat to the side without the hole and went fast enough to keep the hole side out of the water. We took the boat to the dock, tied it up, and went back home.

When we got back dad got dirty looks from the in-laws, or maybe he just thought he did. Walt had a black eye. A few years later when mom and dad split dad needed to sell a boat. His plan was to sell the houseboat but I begged him to keep it and sell the sailboat instead.

Some time later a bunch of his friends went to the houseboat and had a party and somehow sunk it.

I'm bookmarking this for lessons learned/tips & tricks, when I make mine.

Well done!